As I glanced up to see where all this water was coming from I noticed a small iceberg formation on the top of the compressor. The service valve (which I had no idea at the time it was a service valve) was encased in ice. Had I possessed the knowledge that I have now (back then) I would have avoided this iceberg situation; but oh no, not me! This box was going to go down like the Titanic. Innovative Technology, Inc. was nice enough to dispatch a refrigeration repairman to take a look. Morris (heating and cooling?) stopped by and the repairman quickly decided the main problem was insufficient insulation. His solution, wrap everything with PU foam insulation (you can see parts of this which I hadn’t scrapped off in the previous blog post picture). This appeared to fix most of the problems; however, as I would soon learn later it did nothing but help cover up a large slew of existing problems (i.e. manufacturer defects).

Author Archives: slewis

The Lemon Dry Box (Part 3)

Image

I soon found that the reason the gauges weren’t working is that there is a membrane that has to be pierced by the manufacturer. Maybe they got into a hurry? But then I noticed that the drip pan for the refer unit was hanging from the frame by its retaining bolts. That was then I knew there was no quality control. The typical US auto maker syndrome of not turning bolts was already apparent. No biggie I thought. My next issue though cropped up not long after powering on the refer unit. I kept hearing this cracking noise. It was coming from the refer unit itself. When I removed a panel I noticed that the sheet metal shell which someone wrapped to hold the spray can variety PU foam insulation was being held (in part) by duct tape (one seam is shown below). This duct tape was splitting due to the temperature change. The next problem I noticed was all the water collecting on the drain plate (inside the refer unit). This caused extensive rusting of the frame (a portion is shown above as well for your amusement). Then came the real surprise.

The Lemon Dry Box (Part 2)

The Lemon Dry Box (Part 2)

The day when my system one box arrived I was excited. Within a very short period of time I had plumbed in UHP grade nitrogen (at 60 psi) and no sooner did it reach the box then a piece of thermoplastic tubing that runs on top of the solenoid valves for the catalyst bed burst. I can’t blame Innovative Technology, Inc. for that. In fact, at the time they didn’t believe it had happened as according to them the tubing was rated for about 1,000 psi! I took photographs (wish I had retained them) and sent the defective section to Innovative Technology. They figured it was a fluke from the tubing manufacturer (who it was I have no idea) and I continued to use the remaining good section of the tubing (with no further ruptures). Despite this the box consumed large quantities of gas even when not in use. At first I thought this was due to faulty Swagelok components, but as we will see later, it was actually due to the poor connections on top of the solenoid valves (one of which was junk itself) and overall poor design. It was then that I noticed the gauges on the antechambers were not working. This triggered an uneasy feeling in my gut, and it was only the beginning of my troubles with the lemon dry box from hell (i.e. Massachusetts).

The Lemon Dry Box (Part 1)

I want to spend the next several posts talking about my lemon dry box. Experience has taught me (over the years) to not buy goods made in the US. I could list numerous examples of junk, “made in America” products that I have owned over the years (and will do so at a later date). Any more these days I have steadily gravitated to made in Japan or Germany. Of course, anything from China is worthless so I need not comment there. In any event, I strayed from this strategy of mine several years ago and purchased a system one box from Innovative Technology, Inc. Big mistake!

In the following string of posts I will detail all of the numerous problems I have had with this unit. The bottom line for the reader is that I absolutely do not suggest buying this product. If the manufacturer had stepped up to the plate and simply admitted “hey we are to blame, let us correct our mistakes and reimburse you,” then I wouldn’t have to take this stance. Unfortunately, they didn’t even make it into the batter’s box let alone out of the dugout when it came to stepping up to the plate…

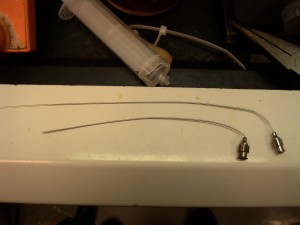

A Difference in Bending Procedure of Needles Leads to Different Results?

Some months ago I ordered a new lot of 12” 20 gauge needles from Fisher Scientific. When they came I noticed that the box had a sticker that said Cadence Scientific instead of Popper and Sons. I took out three needles and very carefully rolled them between a countertop and a semi-truck tire gauge (aka the steel mandrel). I basically did a combination of rolling and also pulling (gently) the needle and the needle hub (as needed) to get the needle to bend in a nice symmetric gradual bend. Well, when I went to use these needles I found that under pressure they leak at the junction between the needle stem and the hub (all three)! I’m going to comment further in a separate post about the nightmare I went through trying to get Fisher to simply send replacements. Anyway, after a long drawn out ordeal I ended up hand bending several of these needles from the same lot (as I had previously hand bent about 40 20 gauge 8” and 6” needles from different lots and none had leaked). Oddly enough when I hand bent the 12” 20 gauge needles they didn’t leak. Can someone tell me why the mandrel bent needles leak and the hand bent don’t even though the radius of the bend in the former is more gradual than that for the latter?

Why this blog?

The purpose of this blog is several-fold. First, it allows me to disseminate updates quickly without having to go through the webmaster. Second, the blog does focus on science related topics so there is some educational value. Third, I intend on reviewing products that I have used over the years. Not just science related but also consumer items. Through my mistakes you will learn without having to suffer similar consequences. Finally, if nothing else this blog should be entertaining to a certain degree and in the very least you can get a chuckle at my expense.